(Press release only available in French.)

Depuis l’installation de AUCHAN au Kirchberg en 1996, l’entreprise LUXENERGIE, produit et fournit sur site chaleur, froid et courant de secours pour le “Stadtteilzentrum Kirchberg”, comprenant l’hypermarché AUCHAN, la galerie commerciale, l’ensemble de bureaux J. BECH occupés par la Commission Européenne, ainsi que l’immeuble KUBIK.

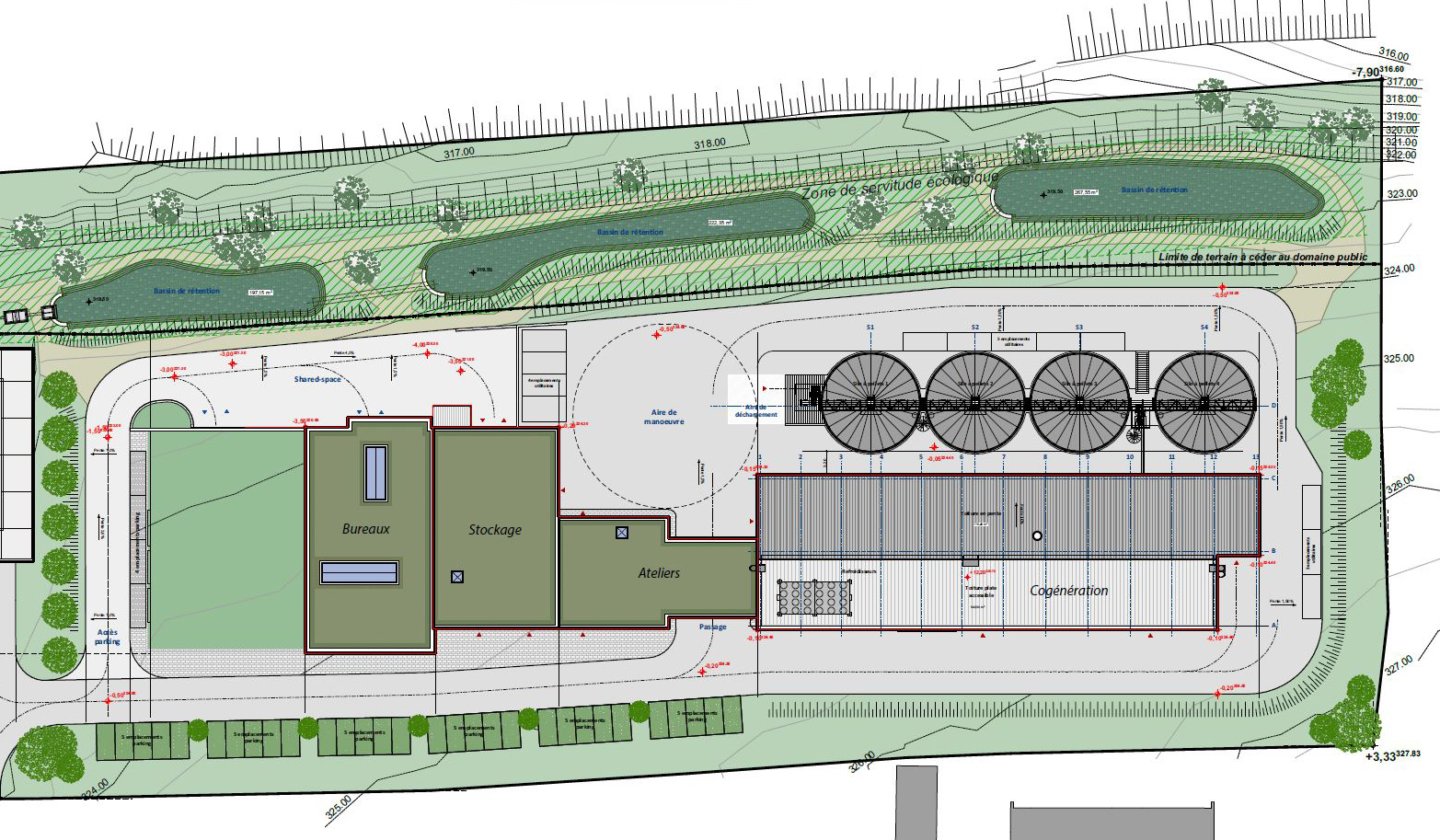

Conçue dans les années 1995, cette centrale

fonctionnant avec des énergies fossiles avait pour vocation d’assurer à

l’ensemble immobilier une totale autonomie de fonctionnement pour palier tous

risques éventuels de rupture de fourniture d’énergie et limiter d’autant le

développement des réseaux publics présents à l’époque sur le plateau.

Fortement engagées dans une démarche de

développement durable et de limitation des impacts environnementaux, les

sociétés LUXENERGIE et NHOOD (mandatées par l’ensemble des propriétaires du

site), entourées des bureaux d’études LUX CONSULT & FELGEN, et de conseil

ARENDT MEDERNACH – ont renouvelé leur collaboration pour les 20 prochaines années

sur la base du remplacement de la centrale d’énergie de cogénération fuel-gaz

en centrale d’énergie à pompes à chaleur air – eau à technologie de CO2

(une première au Luxembourg), alimentées par de l’électricité issue de sources 100% renouvelables.

Elle vise ainsi un

approvisionnement énergétique du complexe totalement neutre en CO2, soit une économie d’environ 2.500 tonnes annuelles de CO2, et la

réduction d’environ 45% des dépenses énergétiques.

Ce projet d’ampleur représente un

investissement de plus de 7 millions d’euros (dont 75% dévolus à des

entreprises luxembourgeoises) pour 35 millions d’euros de fourniture

énergétique cumulée sur la durée.

Les installations actuelles seront

dépolluées et démantelées à destination du marché de seconde main pour les

équipements réutilisables, ou à des fins de recyclage des matières premières

pour les équipements non réutilisables.

Forts de cette expérience commune de

conception du renouvellement de la centrale d’énergie et de l’esprit

constructif manifesté tout au long du processus, les partenaires sont également

convenus d’unir leur savoir-faire afin de mener une politique d’achats

énergétiques commune proactive.

Matteo Perino, General Manager de Nhood Luxembourg souligne : « Nous nous engageons à améliorer la performance environnementale des actifs et quartiers dont nous avons la gestion ou que nous créons. Ce projet, mené de concert, s’inscrit pleinement dans notre volonté de générer dans chacune de nos actions, un triple impact positif : People-Planet-Prosperity ».

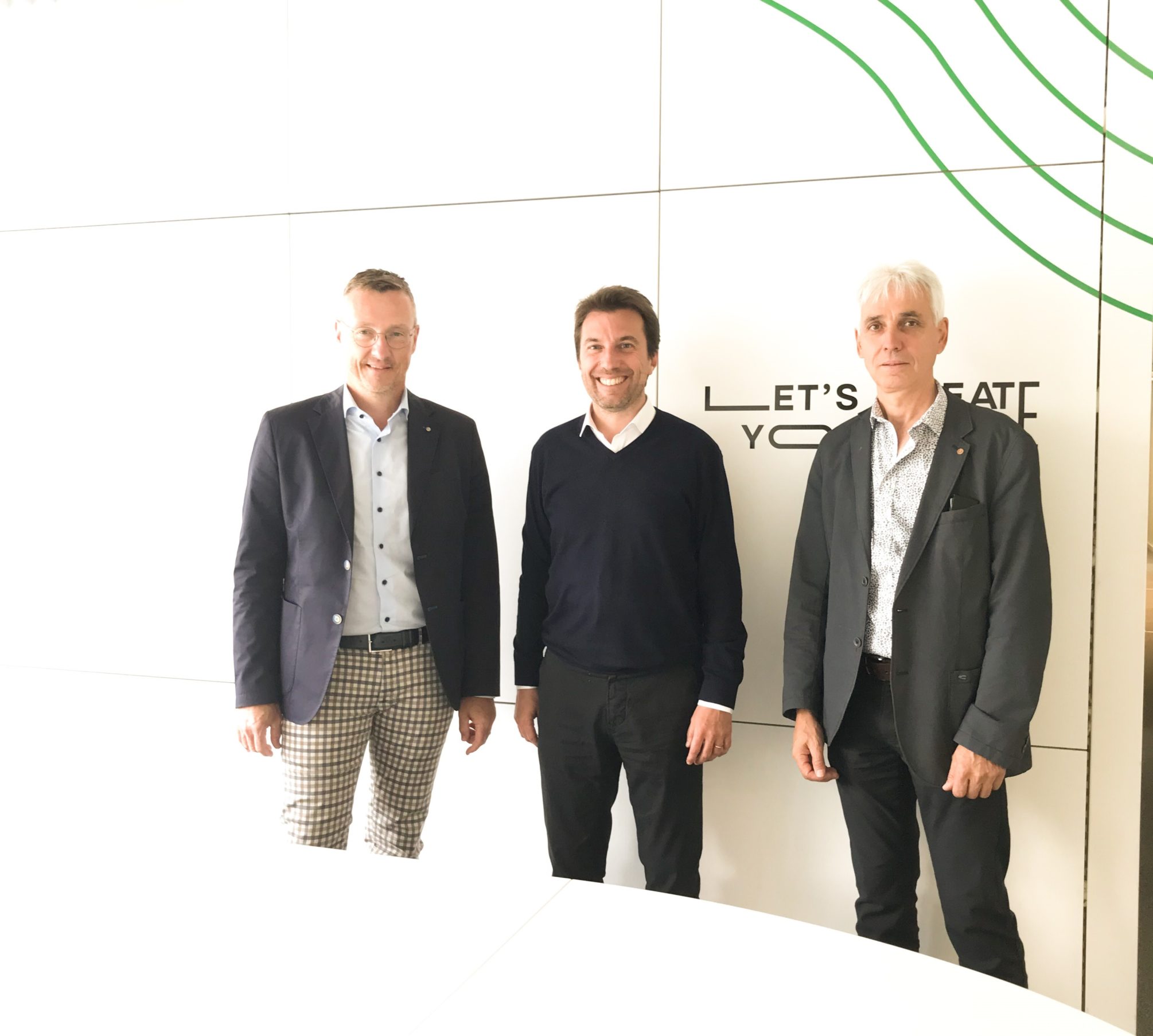

Photo de gauche à droite: Paul Weis, Administrateur Délégué LuxEnergie – Matteo Perino, Directeur Général Nhood Luxembourg – John Sliepen, Chef du Service Technico-Commercial LuxEnergie

Techniquement, la transformation consiste à remplacer les trois cogénérations au gaz, ainsi que les cinq machines frigorifiques, par quatre pompes à chaleur air-eau réversibles. Le CO2 haute pression utilisé dans les pompes à chaleur, est un réfrigérant parfaitement naturel, aux qualités environnementales optimales.

Ces

pompes à chaleur peuvent fonctionner dans trois modes différents :

- Mode

chauffage, à partir de l’air ambiante et activé grâce à l’électricité verte,

l’eau est chauffée à 75 °C et injectée dans le réseau de chaleur en

hiver ;

- Mode

climatisation, le cycle est inversé pour refroidir le bâtiment. La chaleur est

extraite du bâtiment et évacuée vers l’extérieur au moyen de ces mêmes pompes à

chaleur ;

- Mode combiné,

la chaleur à évacuer lors de la production du froid est portée au niveau de

température du réseau de chaleur. Il en résulte un rendement particulièrement

optimal.

Les pics de demande d’énergie en chaleur (< 5% des besoins), sont couverts par des chaudières existantes alimentées par du biogaz.